WaStop®

Inline check valve

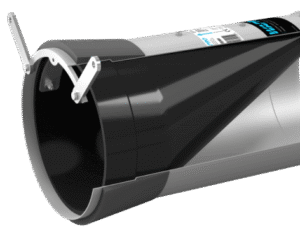

WaStop Inline check valve provides direct and reliable protection against flooding and backflow in wastewater and stormwater systems. With its unique self-sealing design, WaStop effectively stops not only water from flowing backward but also blocks odors and pests, making it an excellent safeguard for both people and property. The valve’s simple yet ingenious function is instantly activated by pressure changes in the pipes – with no need for electricity – making it a sustainable, maintenance-free solution.

Area of use:

WaStop models

Here you’ll find our range of WaStop check valves – tailored for various needs, sizes, and installation types.

Missing something or not sure which model is right for your facility? Don’t hesitate to contact us – we’ll help you find the right solution!

Does this sound interesting?

Contact the responsible sales representative for more information.

Richard Neal

South East Regional Sales Manager

richard.neal@wapro.com

+1 407-398-9868

Charlie Sullivan

Territory Sales Manager (DC, IL, MD, NC, SC, VA)

charlie.sullivan@wapro.com

+1 407-625-0200

Marcus Morieko

Territory Sales Manager (NJ, DE, PA)

marcus.morieko@wapro.com

+1 732-228-1704

Kathy Bielert

Inside Sales Coordinator

order@wapro.com

+1 860.287.7235

Product overview

WaStop Inline check valve

Ingeniously simple and built to last – WaStop is a fully automatic, maintenance-free solution that protects against backflow, flooding, and odors – all without electricity or manual intervention. Its unique self-sealing differential pressure system allows WaStop to operate seamlessly in any installation environment, with sizes available from DN75 up to DN2000. This makes it a flexible choice that not only protects properties but also supports more sustainable water resource management.

Why WaStop is a sustainable choice for future flood protection

- Advanced protection with minimal effort: WaStop is a technically advanced solution that safeguards drainage systems without requiring a power supply, resulting in energy savings over the product’s lifespan.

- Efficient flow management: The patented self-sealing system activates only when needed, optimizing flow characteristics and reducing pressure loss.

- Environmental benefits through contamination prevention: Prevents wastewater from entering clean water sources and lowers the risk of environmental damage during extreme weather events.

- Durable and chemical-resistant construction: Designed to withstand both mechanical and chemical stresses, providing a long-lasting solution with minimal operational disruption.

- Flexible installation: Adapts to various pipe sizes and flow conditions, making it ideal for municipal as well as private applications.

Installation

Easy installation, immediate protection

The WaStop Inline check valve is designed for quick and straightforward installation, providing immediate protection against backflow, flooding, and unwanted odors. Thanks to its flexible design, WaStop can be installed in existing pipe systems, manholes, or on walls – either horizontally or vertically – with no need for electricity or control systems.

A standard installation takes about 30–60 minutes depending on the size and location. Most municipalities and contractors can perform the installation themselves without external assistance, saving both time and money.

WaStop is delivered with clear installation instructions and requires only minimal tools. For proper sealing, included rubber gaskets or, if necessary, swellable sealants are used.

Whether for new installations or retrofitting into existing systems, WaStop offers a reliable, maintenance-free solution for effective flow control.

Animations

Smart protection you can trust!

Our animations show how the WaStop Inline check valve automatically protects against flooding, unpleasant odors, and backflow. With its patented flexible membrane design, WaStop instantly reacts to pressure differences, shutting off unwanted flows.

No electricity, no maintenance – just smart, reliable protection around the clock. Discover why thousands of users worldwide choose WaStop for their flow control needs.