WaBack®

Non-return chamber

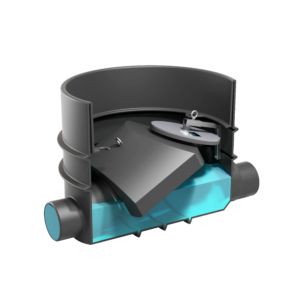

The WaBack Non-return chamber is a robust and highly effective solution that protects properties against backflow and flooding in wastewater and stormwater systems. With its innovative, self-sealing design, WaBack provides automatic and immediate protection without the need for electricity or manual operation. Its clever construction ensures unrestricted flow under normal conditions and only activates when needed, offering maintenance-free, sustainable protection for both properties and the environment.

Area of use:

WaBack models

Here you will find our range of WaBack Non-return chambers – tailored for different needs, sizes and installation types.

Missing something or unsure which model suits your system? Do not hesitate to contact us – we will help you find the right solution!

Interested?

Contact our sales representative for more information.

Marcus Morieko

Territory Sales Manager (NJ, DE, PA)

marcus.morieko@wapro.com

+1 732-228-1704

Richard Neal

South East Regional Sales Manager

richard.neal@wapro.com

+1 407-398-9868

Kathy Bielert

Inside Sales Coordinator

order@wapro.com

+1 860.287.7235

Product overview

WaBack Non-return chamber

Self-activating, reliable, and built to last – WaBack® is a dependable, effective solution for protecting properties against backflow and flooding in wastewater and stormwater systems. Its unique design provides immediate, automatic protection, especially well-suited to handle heavily contaminated water. The fully open flow area ensures clog-free operation, minimizing the risk of blockages and reducing maintenance needs.

Why WaBack is a sustainable choice for future flood protection

- Automatic and energy-efficient protection: WaBack is activated by water flow without the need for electricity, reducing energy use and operating costs while supporting sustainable practices.

- Protection of water quality and ecosystems: Prevents contaminated wastewater from reaching drinking water sources and natural waterways, protecting both the environment and public health.

- Optimal flow capacity and less maintenance: The open design ensures free flow under normal conditions, minimizing blockages and lowering the need for chemical cleaners and resource-intensive maintenance.

- Easy installation and long service life: Made from durable, corrosion-resistant materials for simple inspection and long-lasting performance, reducing the need for frequent replacements and saving resources.

- Lower environmental impact from repairs: By preventing flood damage to buildings, WaBack reduces resource use and the carbon footprint associated with cleanup and repair efforts.

Downloads

At Wapro, we believe in opportunities. By being an open organization, we learn from our customers and are always happy to share our knowledge. Below you’ll find all the information about our products along with other useful and interesting materials. Contact us if there’s anything you’re missing.

Installation

Quick installation for immediate protection

The WaBack Non-return chamber is designed to provide fast and effective protection against flooding and backflow. Delivered as a complete unit that combines an inspection chamber with an automatic non-return valve, it significantly simplifies the installation process.

The installation is highly flexible and can be adapted to existing pipe systems. WaBack can be installed in various types of pipelines and is compatible with sizes from DN110 to DN315. To ensure proper function, the chamber should be installed at the same slope as the pipe since it does not have a built-in gradient. It’s important that the flow direction in the chamber matches the flow direction of the pipes.

To make installation even easier, a range of accessories is available, including riser pipes, reduction cones, and chamber lids in various sizes. When installing in areas exposed to groundwater pressure, the product should be securely anchored to prevent it from floating. This is especially important for the WaBack Access Large, where the maximum installation depth is 2.5 meters from the pipe invert to ground level.

WaBack requires minimal maintenance and is made from corrosion-free materials for long-lasting performance. For added safety, it can be supplemented with a water level alarm that provides both visual and audible alerts if water levels rise.

With WaBack, you get a reliable, sustainable solution to protect your property against flooding, with an installation process that is both simple and cost-effective.

Animations

Reliable flood protection you can count on!

Our animations show how WaBack effectively prevents flooding from drainage systems during heavy rain and extreme weather. Thanks to its robust design and self-activating function, WaBack delivers reliable protection exactly when you need it.

No manual activation, no hassle – just dependable, automatic protection 24/7. Discover how WaBack safeguards properties around the world and why it’s the go-to choice for reliable flood control.