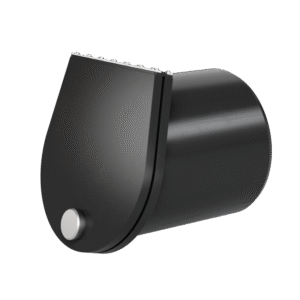

WaFlap™

Flap Valve

WaFlap flap valves are a versatile and effective solution for protecting against flooding and backflow. These flap valves are designed to meet a wide range of needs, from serving as emergency shut-offs along roads to preventing backflow at pumping stations. With a variety of models, WaFlap flap valves can be customised to ensure optimal performance in any situation.

Area of use:

WaFlap Models

Here you will find our range of WaFlap Flap valves – tailored for different needs, sizes and installation types.

Missing something or unsure which model suits your facility? Don’t hesitate to contact us – we’ll help you find the right solution!

Interested?

Contact our sales representative for more information.

Product overview

WaFlap Flap valves

Efficient, durable and reliable – WaFlap Flap valves are designed to provide effective protection against flooding and contamination in wastewater systems. Their robust design and use of corrosion-resistant materials ensure long-lasting durability and minimal maintenance, making them ideal for both municipal and industrial applications. WaFlap flap valves are easy to install and can be easily adapted to different pipe sizes and installation requirements. By effectively blocking backflow, they not only protect infrastructure but also help maintain water quality and safeguard ecosystems. With WaFlap flap valves, you can be confident you have a reliable solution for managing water flows and protecting against unwanted flooding.

Why WaFlap flap valves are a smart choice for simple and effective backflow protection

- Effective flood protection: WaFlap Flap valves efficiently prevent backflow and flooding, protecting properties and infrastructure from damage caused by unwanted water volumes.

- Robust and durable construction: Made from corrosion-resistant materials, these flap valves offer a long lifespan and minimal maintenance, saving time and resources.

- Flexible installation: WaFlap Flap valves can be adapted to different pipe sizes and installation environments, making them suitable for a wide range of applications, from municipal systems to industrial facilities.

- Protection of water quality: By effectively preventing backflow of contaminated water, WaFlap flap valves protect drinking water reserves and natural watercourses, contributing to the preservation of ecosystems and biodiversity.

- Reduced risk of environmental damage: By preventing flooding, flap valves reduce the risk of erosion and soil degradation, which is crucial for maintaining a sustainable and stable environment.

Installation

Easy installation for immediate protection

WaFlap Flap valves are designed to be mounted quickly and easily directly onto pipe outlets, providing immediate protection against backflow and flooding. Thanks to their compact and robust design, they are excellent for both new and existing installations – whether in urban environments, coastal areas or rural settings.

The valve is installed directly on a wall or pipe flange using the supplied bolts and seal. The installation requires no special tools and can usually be carried out by municipalities or contractors without external help.

Because WaFlap Flap valves operate entirely mechanically, there is no need for electricity, sensors or control systems – making the installation smooth, cost-effective and reliable from day one.

Animations

Protection that seals at just the right moment

Our animations show how WaFlap Flap valves automatically close on backflow, protecting against flooding – completely without electricity or manual intervention. Under normal flow conditions, the valve opens easily, but closes immediately in response to backpressure from, for example, high water levels, tides or floods.

Simple function, robust construction and reliable protection around the clock – see for yourself how effectively WaFlap prevents intrusion into vulnerable wastewater systems.